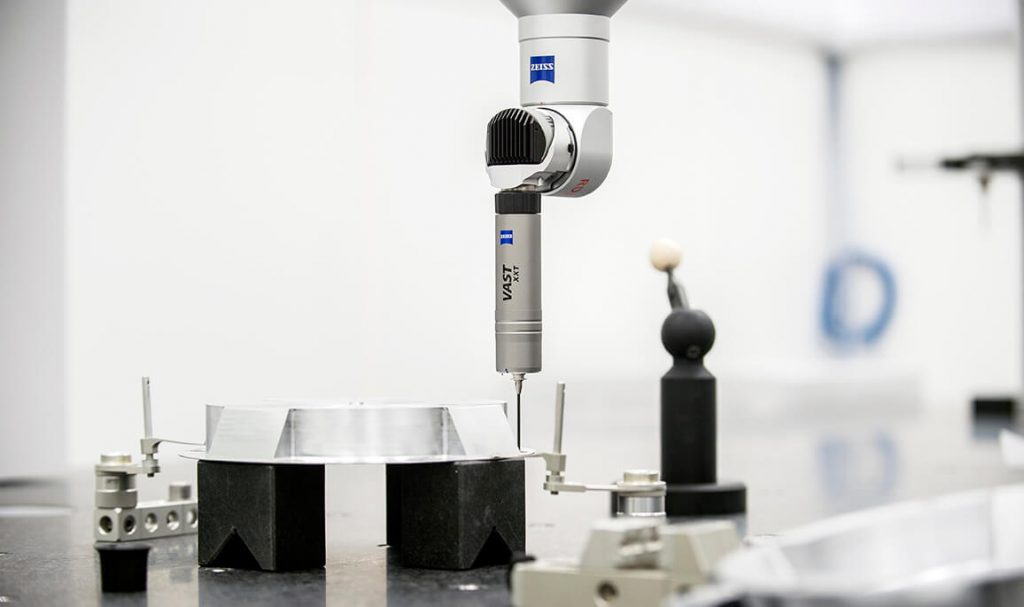

They have achieved a breakthrough in aerospace engine technology by developing ultra-lightweight heat exchangers. These are 100 times lighter than current hardware, capable of cooling airstreams from over 1,000°C to -150°C in less than 1/100th of a second. SABRE, and its breakthrough technology, will enable aircraft to fly over five times the speed of sound in the atmosphere and allow launch vehicles to be built that will radically improve the affordability and responsiveness of access to space. In 2014 OxLEP identified space related technologies in its strategic economic plan as an important sector to attract foreign direct investment and a focus for research & development projects. A project and opportunity was identified for Reaction Engines within the Growing Places Fund and in 2015 the company was awarded £140k as an investment 5 year loan to set up a Quality Assurance department and new QA machinery within their manufacturing facilities in Didcot Park. As a direct result of the funding, Reaction Engines employed a Quality Assurance Manager, a Skilled Inspector and an Apprentice to train on the newly installed equipment. This has led to market leading quality assurance on our manufacturing output (to tolerances of under a micron); an essential part of the manufacturing process as precision and quality are critical for the system parts and components of the SABRE project. Tom Scrope, Chief Financial Officer for Reaction Engines commented during a recent fund review, “The loan allowed us to quickly establish and equip the QA team and has made a real difference to our business. We were able to demonstrate high quality standards which were instrumental in forming the partnership later in the year between us and BAE Systems. We have also strengthened our leadership team and local Oxfordshire based workforce, contributing to supporting the growth in the UK space sector”. The new team and state-of-the-art Zeiss CMM part inspection equipment are based at Reaction Engines subsidiaries Brite Precision and Crossman Engineering who offer precision manufacturing and fabrication services.

Quality is ensured by this equipment and ISO 9001 quality management. Reaction Engines is supported by the UK Space Agency and European Space Agency. They have had a recent £20.6m investment by BAE Systems and a £60m commitment from the UK Government. They have also begun partnering with aerospace suppliers to deliver a ground-based SABRE demonstrator engine.