Precooler. From over 1,000°C to ambient in the blink of an eye

Our precooler technology is already transforming what’s possible in the world of heat management.

Home > Capabilities > Precooler

A key component in the development of our ground-breaking SABRE engine

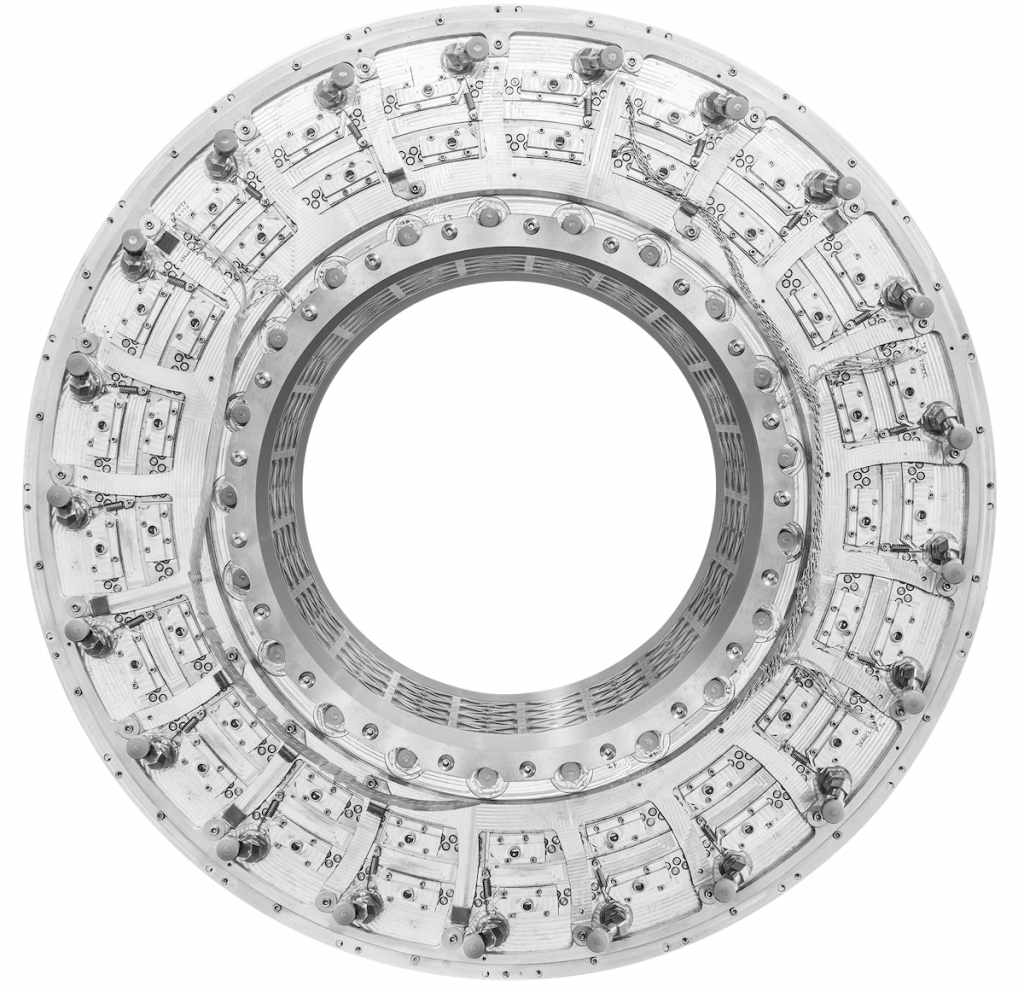

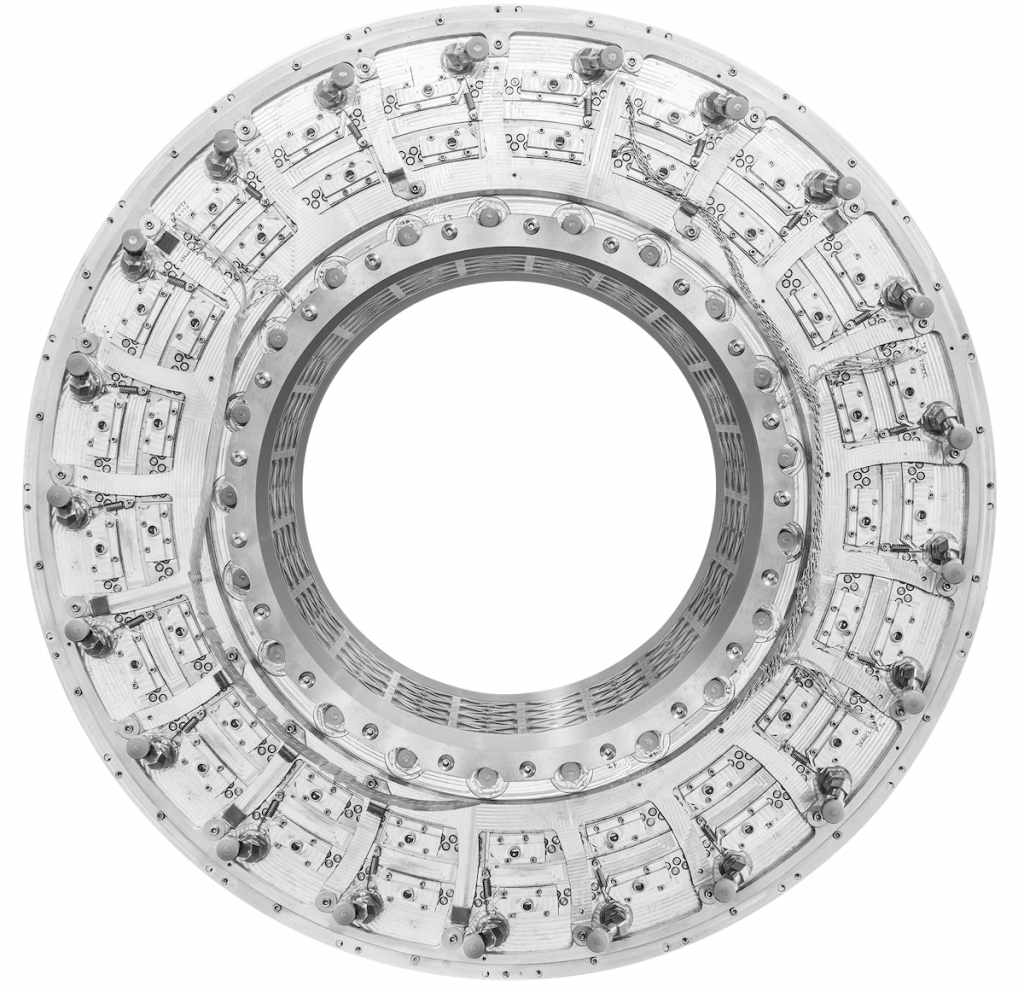

Powerful injection

Coolant is injected and removed via inlet and outlet manifolds connected to each cooling tube.

Cylindrical Cooling

By bringing together thousands of thin-walled tubes in a cylindrical formation, we create optimum surface-area-to-weight ratio.

Seamless Bonding

In a world first – our expertise allows us to bond thousands of joints in a single operation.

With zero leakage.

The precursor to our thermal management solutions

Combining thousands of thin-walled tubes to provide an optimum surface-area-to-weight ratio, each tube is joined to an inlet and outlet manifold to allow coolant to be injected and removed for an extremely efficient and effective cooling process. We are world-leading experts in the development of heat exchanger manufacturing, bonding thousands of joints in a single operation, with zero leakage.

Aerospace

Defence & Space

Motorsport

Energy

News

Now proven at

Mach 5 speeds

In October 2019, our HTX test programme carried out a ground-level demonstration of the precooler technology at Mach 5 airflow temperatures – proving the potential of this innovation at five times the speed of sound and marking a significant milestone in the development of SABRE.

Let's talk

Ready to explore how our game-changing heat management solutions, including advanced charge air coolers and radiators, can revolutionise your industry? Contact us today to learn more.