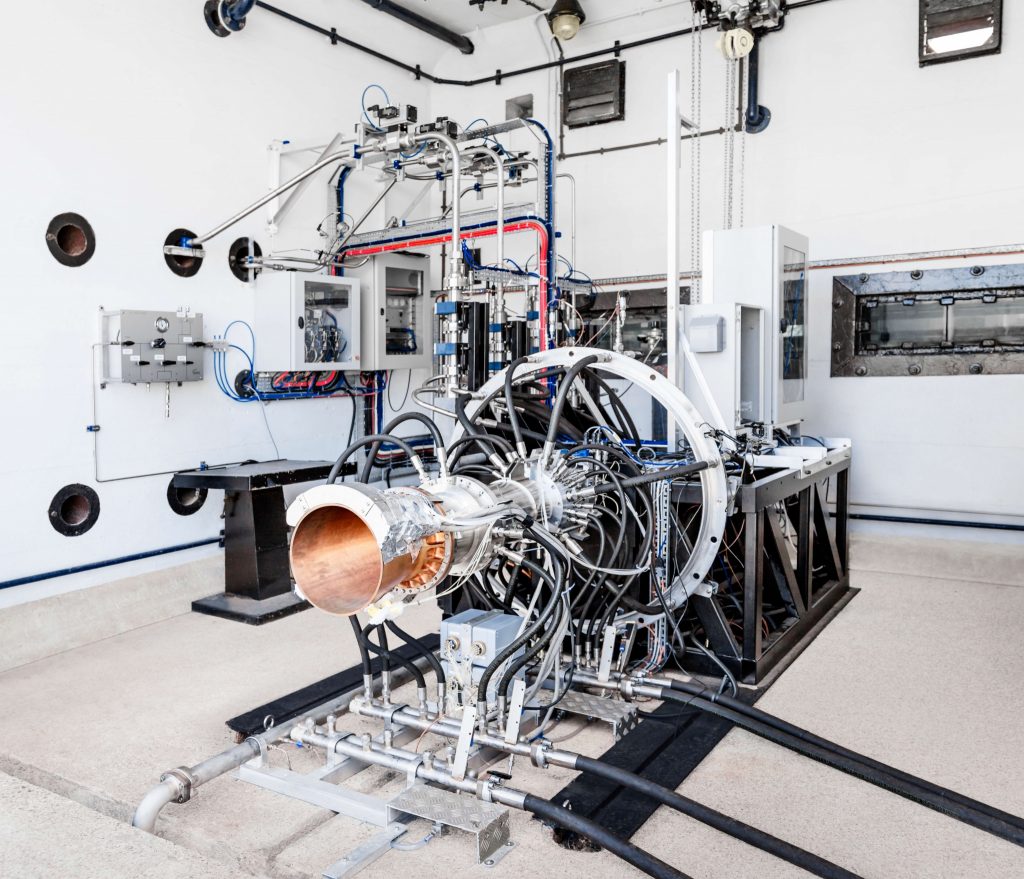

The test engine, which has been successfully fired 15 times during its initial commissioning phase in spring 2015, incorporates several new technologies including a 3D printed, actively cooled propellant injector system. Aerodynamic data collected from the firings is being used to validate in-house computational modelling and advance the nozzle design. The test campaign is being operated by Airborne Engineering Ltd in Westcott, Buckinghamshire. Operations are planned to continue throughout 2015, including long duration burns and tests investigating the transition between air- breathing and rocket operation planned for later in the year. Dr Helen Webber, Reaction Engines’ Project Lead for the Advanced Nozzle Programme, commented: “This experimental engine is an important step into a new era of propulsion and space access. We are using it to test the aerodynamics and performance of the advanced nozzles that the SABRE engine will use, in addition to new manufacturing technologies such as our 3D-printed injection system. The testing of new propulsion technology has required close work with our partners at Airborne Engineering, in order to make a test rig that can simulate the unique and demanding range of conditions required to put this engine through its paces. Despite being much smaller than SABRE, this engine is still the largest bi-propellant engine to be tested at Westcott for over thirty years, and it is exciting to see the resurgence of Westcott as the centre for UK rocket propulsion research and development. The next few months will see us running the engine for much longer periods in order to explore the transition between the air-breathing and rocket modes of the SABRE’s flight – an important and challenging part of powering Skylon into space.” https://vimeo.com/130617927